[Technical Information] What is a data acquisition system (RFID)?

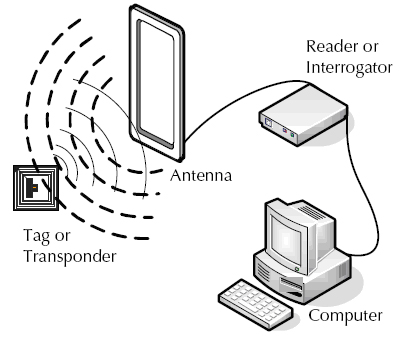

For RFID, you may go online to check RFID related information: “RFID abbreviation: Radio Frequency IDentification. It is a wireless communication technology that can identify specific targets and read and write related data through radio signals without identifying the system and specific targets. Establish mechanical or optical contact between them.” Before introducing it, you must understand its structure and make the concept correct. We can explain through the following structure diagram:

For KWD, when RFID is applied to the manufacturing end, it will become the nerve system of the factory’s operation. It will recognize its product components wirelessly, and through the distribution of RFID at the control point, all production components in the factory (including Warehouse, production line, shipment tracking, production history) or production equipment management (property number, data verification, etc.). Through information reading and writing, back to the database, providing the most real-time information, which is beneficial MES and ERP do data selection to achieve real-time and accuracy, and greatly reduce manpower and improve production efficiency. The original meaning of this system is called RFID Data Acquisition System.

The general RFID capture system contains three kinds of hardware (tags, antennas, readers). Due to the difference in factory usage, it is often necessary to change the design to meet the stability of the system. The order of changes is tag>antenna>read and write Device. The main reason is that the material, structure, and use environment of the label affixed to the managed objects are different, such as textiles, metals, cables, and other objects, which will cause the label characteristics to change and require adjustment. As for the antenna part, we divide the antenna into three categories (near field, far field, induction field). It can be optimized according to the standard used by the customer to achieve the optimized wireless Transmission efficiency.

1. According to the material, structure, and use environment of the managed items, the standard is customized.

2. It can be customized according to the environment, polarization mode, fixed mode, size, and reading requirements.