[Technical Information] What is the MES system? What does it have to do with RFID! ?

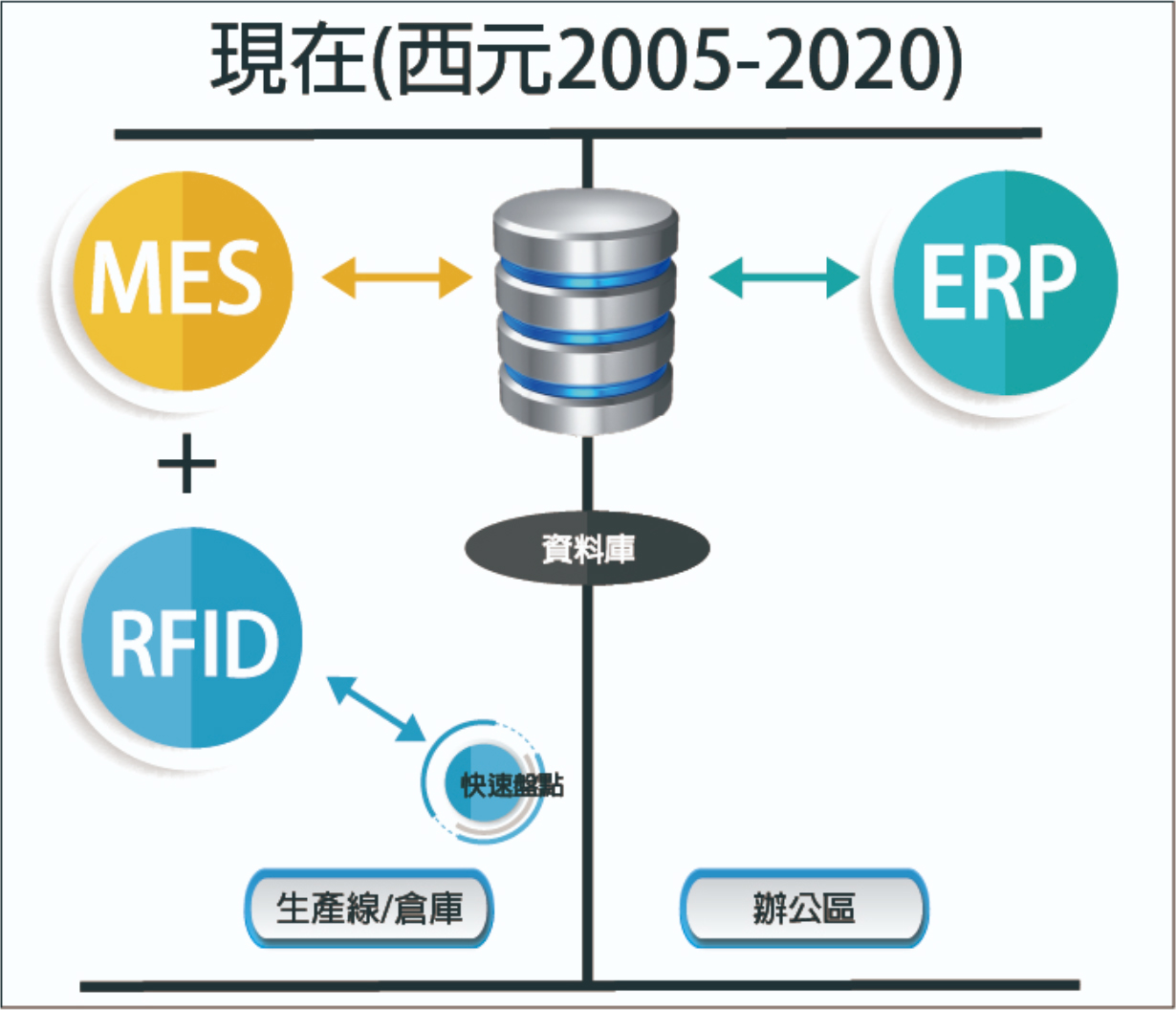

Most large-scale production plants are equipped with two sets of management systems: ERP and MES systems, among which the ERP (Enterprise Resource Planning) system is mainly for management, sales, inventory, personnel, and other matters, and is involved in the actual production process of the factory. And MES (Manufacturing Execution System) is a system that integrates work orders, production, equipment management, maintenance, quality control to warehouse storage, import and export, etc. It can be said to be the core of a manufacturing factory.

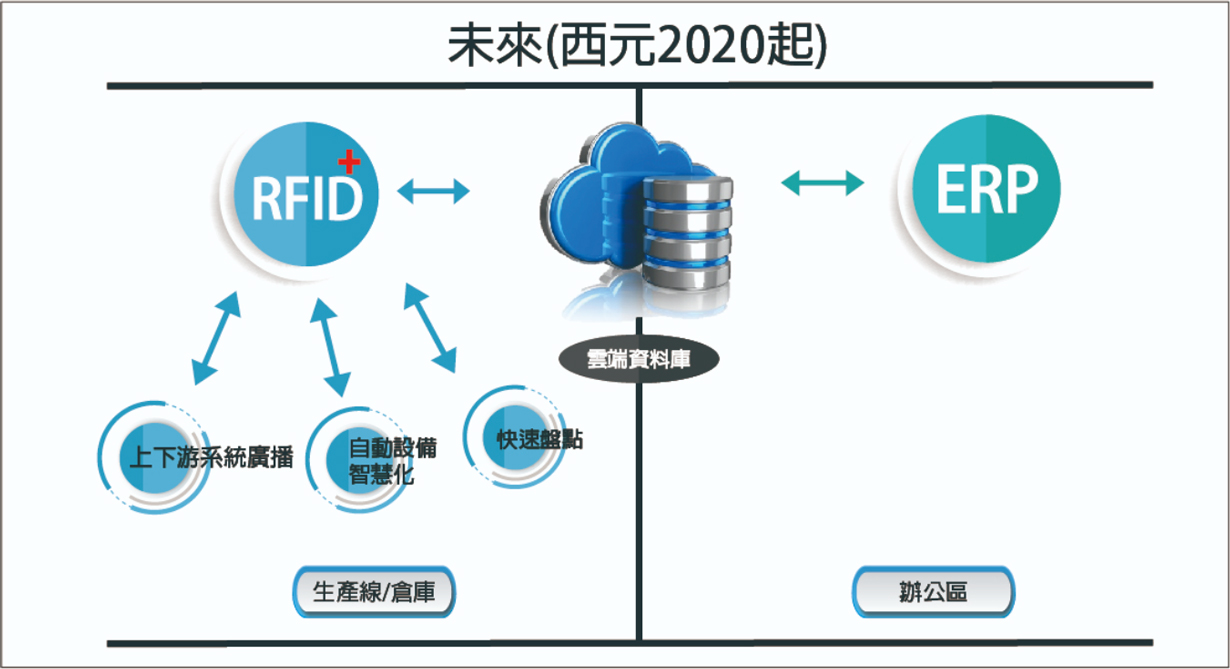

When the parts are picked out from the warehouse and sent to the production line for assembly, they flow to different production lines due to different specifications, put them into different packages, and then ship points. Each work section is recorded and counted manually. If the factory area is too large or the production quantity is large, manually input the MES system one by one, which wastes manpower and time, and the RFID solution contains software and hardware execution, not only can Auxiliary MES system, through the interface software, but can also be input into the MES system in large quantities and in real-time. The principle of one thing, one code, and the code does not repeat. At the same time; in the case of a unique code in the world, it can perform product tracking, resume, anti-counterfeiting, and other functions, which can meet real-time updates and be used as a basis when the production line equipment changes actions. If the factory installs a nervous system, it can determine its Relevant information, make corresponding responses, and achieve the goal of Industry 4.0.